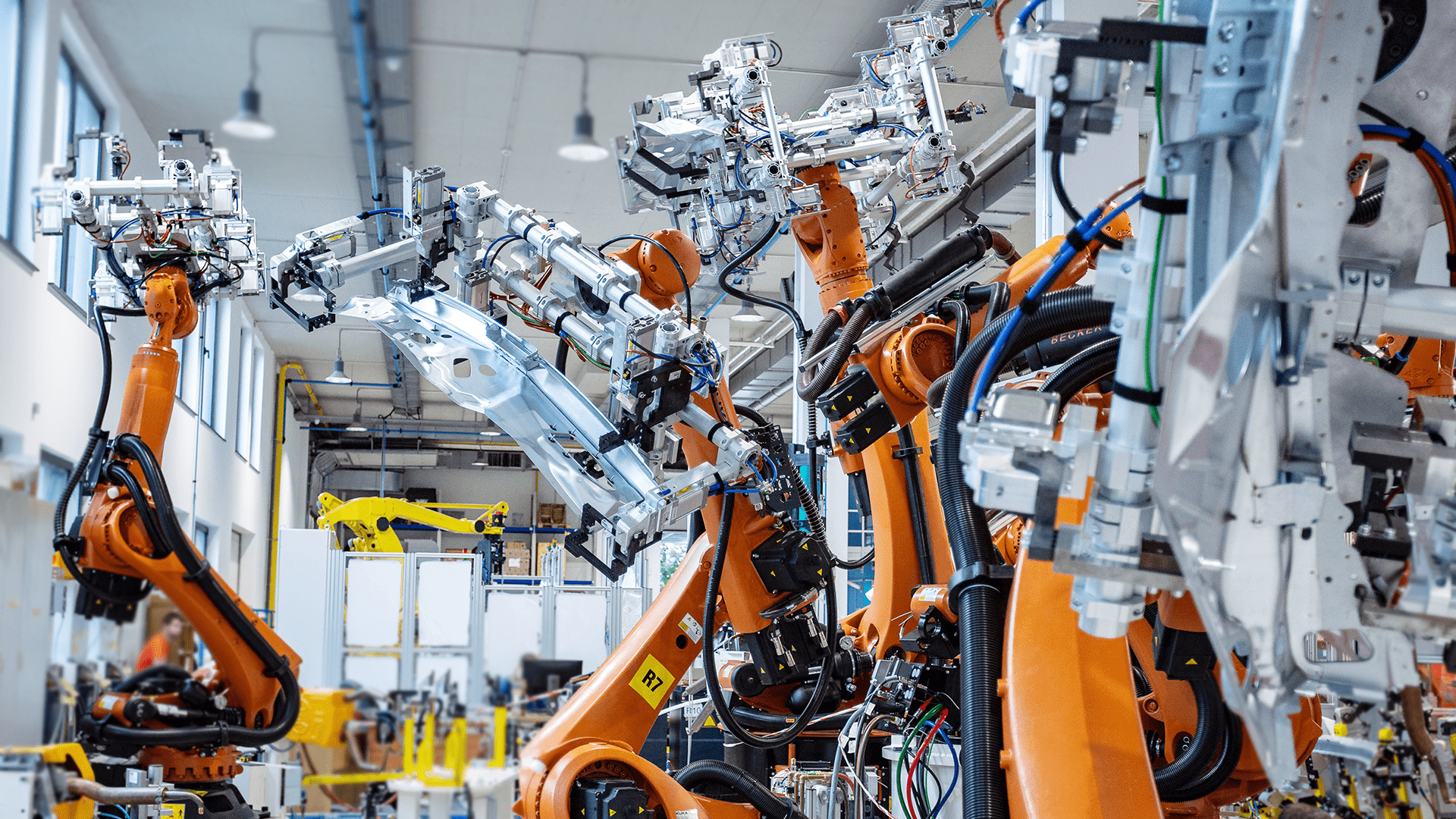

We design, we integrate, we create advanced solutions in the area of automation and robotization of production processes, along with production control and management for customers around the world. We deliver our solutions in a turn-key model.

30 years of experience in production automation

We provide our clients with modern machines, robotic production lines and stations. We are capable of delivering entire factories as well. We perform a complete implementation of a project in the scope of automation, electricity, production line construction and production management systems - including the assembly, start-up and servicing tasks.

Comprehensive implementations

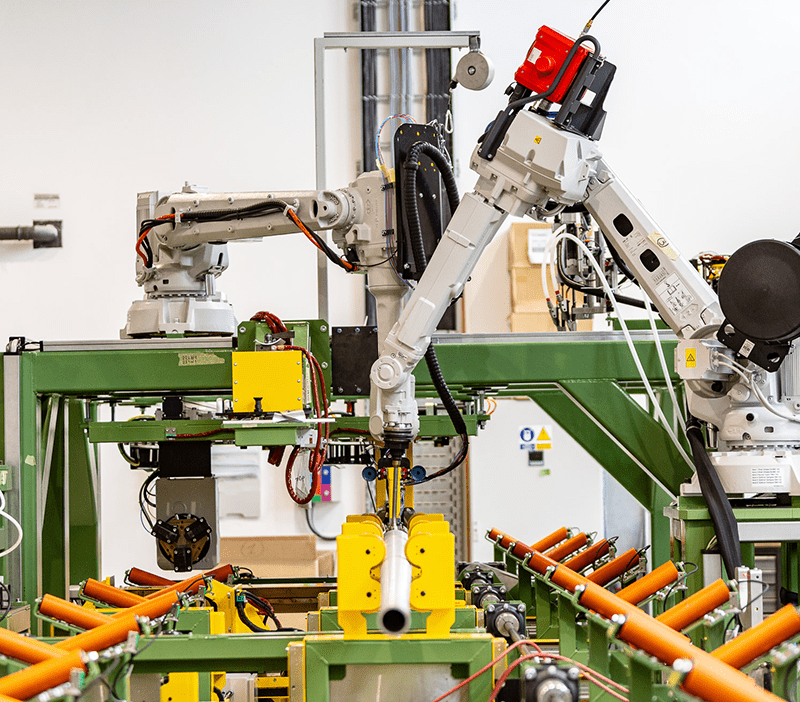

We create comprehensive solutions in the field of manufacturing processes automation and robotization - beginning with conceptual implementation, through virtual implementation, all way up to the turn-key launch of robotic production lines and stations. We deliver and provide on-premises assembly of control and electrical cabinets, assembly of cable routes, cabling, electrical equipment, and I&C. We conduct functional tests and trials as well as machine start-ups and inspections.

Operation reliability

We design and manufacture our solutions using the state-of-the-art, top-quality components from global producers and suppliers for automation. This ensures the stability and reliability of our installations. Warranty and post-warranty service is a natural perspective for further cooperation with AIUT.

- Advanced solutions in robotics and mechatronics

- 600+ highly-qualified engineering specialists

We ensure:

- comprehensive management of the investment,

- complete start-up process,

- integration of systems,

- delivery and on-premises installation,

- support services throughout the entire life cycle of the system,

- warranty and post-warranty service.

We create and modernize

Our broad technological competence allows us to create flexible systems for production and business process management, responding to the diverse needs of enterprises. Our solutions increase the efficiency and pace of manufacturing and logistics processes. Robotic lines and production stations that our company provides, bring new opportunities for business development to our partners. AIUT services also include modernization of existing infrastructure, its adaptation to new needs and conditions, and ongoing service.

We design and integrate systems

We design and supply control systems, implement I&C projects with programming and visualization. We develop PLC and DCS software, SCADA systems and dedicated software for detection and production management systems.

- Designs of power supply and control systems - complete electrical project

- Designs of Instrumentation and Control devices and systems (I&C)

- Software and visualization projects (DCS, PLC, SCADA)

- logic controllers programming (PLC)

- process monitoring systems programming (SCADA)

- Distributed Control Systems programming (DCS)

- Creating dedicated software for production tracking and management systems

- Virtual commissioning

- Assembly and testing of production stations and lines in the AIUT mechanical workshop

- Prefabrication of electrical and control cabinets in our own electrical workshop

- Installation of cable routes, cabling, electrical equipment and I&C (control and measurement instruments and automation)

- On-site assembly and commissioning by teams of AIUT specialists

Warranty and post-warranty service

We know how important business continuity is. That is why we provide our clients with a full warranty and post-warranty service for implemented projects, throughout the entire investment life cycle. This is a common complementary practice while working with AIUT. With the highest standard of services in mind, we provide the option of our qualified 24/7 support service.

Guarantee of business benefits (PRaaS)

We are a mature business partner. Our solutions allow enterprises to significantly optimize processes and reduce costs, as well as improve the quality of services provided. To support these declarations, a flexible approach to achieving business benefits as part of our projects is brought.

We offer various scenarios for cooperation - from technical support and consulting in traditional models, to sharing responsibility for achieving goals (KPIs) for specified areas in the PRaaS model - Process Responsibility as a Service - which guarantees business benefits for AIUT partners.